Eliminate Contamination Within Your Workspace

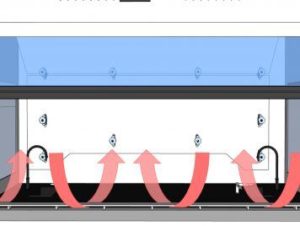

Our Laminar flow cabinets create ISO 5 (Class 100) cleanroom conditions using high-quality H14 HEPA filters and advanced UV technology. These filters remove 99.97% of all airborne particles >0.3 μm in size, eliminating the risk of sample contamination within your workspace. With horizontal and vertical models available, we offer a series of portable, cleanroom alternatives designed to optimise the space inside your facility and reduce operating costs.

TION's manufacturing process enables full cabinet customisation at no additional cost. Our products prioritise safety, accessibility and ergonomics, allowing you to create the perfect cabinet for any application regardless of size. With a suite of gas taps, workbench materials, stands, power sockets and models to choose from, there's no request too complicated for our experienced design teams. Contact our sales department today for more information.

Our optional 316 stainless steel and multi-piece work surfaces can provide a greater degree of corrosive protection and simplify the cleaning process.

ISO 4 and ISO 5 standards are used to classify controlled workspace environments based on the number of airborne particles per cubic meter of air.

The level of protection you choose depends on your application or process.

Lighting is an important part of your laminar flow cabinet specification. Our energy-efficient 800 LUX LED lights provide excellent clarity and last longer than older fluorescent tubes.

Bench-mounted laminar flow cabinets are stationary units fixed to a pre-existing work surface. The products are ideal for laboratories short on space but lack the manoeuvrability of stand-mounted units.

Our upgradable 7" digital control panel is touch-screen ready, creating a seamless user experience. The programmable software tracks air inflow and downflow, annual commissioning dates and filter replacements. It's also equipped with a state-of-the-art red-light alarm system. This vital safety function visually notifies the operator if an airflow drop is detected.

Maintaining a safe and secure work zone is paramount to our product design process. Our cabinets adhere to ISO standards and feature a UV sterilisation light to remove contaminants between your working processes.

| Model | LAF900-VP | LAF1200-VP | LAF1500-VP | LAF1800-VP |

|---|---|---|---|---|

| External Size (W x D x H) | 900 x 850 x 1320 mm 35.4 x 33.4 x 51.9″ | 1200 x 850 x 1320 mm 47.2 x 33.4 x 51.9″ | 1500 x 850 x 1320 mm 59 x 33.4 x 51.9″ | 1800 x 850 x 1320 mm 70.8 x 33.4 x 51.9″ |

| Internal (workspace) Size (W x D x H) | 770 x 700 x 750 mm 30.3 x 27.5 x 29.5″ | 1070 x 700 x 750 mm 42.1 x 27.5 x 29.5” | 1370 x 700 x 750 mm 53.9 x 27.5 x 29.5” | 1670 x 700 x 750 mm 65.7 x 27.5 x 29.5” |

| Production / Test Standard | ISO-14644-1, CE | ISO-14644-1, CE | ISO-14644-1, CE | ISO-14644-1, CE |

| Air Velocity | 0.3 m/s, 60 FPM | 0.3 m/s, 60 FPM | 0.3 m/s, 60 FPM | 0.3 m/s, 60 FPM |

| Workstation Cleanliness | Class-100 (FS 209E) ISO 4, ISO-14644-1 | Class-100 (FS 209E) ISO 4, ISO-14644-1 | Class-100 (FS 209E) ISO 4, ISO-14644-1 | Class-100 (FS 209E) ISO 4, ISO-14644-1 |

| Cabinet Material | Polypropylene | Polypropylene | Polypropylene | Polypropylene |

| Work Surface Material | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel |

| Noise Level | <50dB | <50dB | <54dB | <54dB |

| Power Supply | 110 / 220V, 50/60 Hz, Single phase | 110 / 220V, 50/60 Hz, Single phase | 110 / 220V, 50/60 Hz, Single phase | 110 / 220V, 50/60 Hz, Single phase |

| Illumination | 800 LUX LED lighting | 800 LUX LED lighting | 800 LUX LED lighting | 800 LUX LED lighting |

| Filter Types | HEPA Filter Efficiency @ 99,9997% @ 0.3 Microns H14 (Optional ULPA filter) | HEPA Filter Efficiency @ 99,9997% @ 0.3 Microns H14 (Optional ULPA filter) | HEPA Filter Efficiency @ 99,9997% @ 0.3 Microns H14 (Optional ULPA filter) | HEPA Filter Efficiency @ 99,9997% @ 0.3 Microns H14 (Optional ULPA filter) |

| Model | LAF900-HP | LAF1200-HP | LAF1500-HP | LAF1800-HP |

|---|---|---|---|---|

| External Size (W x D x H) | 900 x 930 x 1200 mm 35.4 x 36.6 x 47.2” | 1200 x 930 x 1200 mm 47.2” x 36.6 x 47.2” | 1500 x 930 x 1200 mm 59 x 36.6 x 42.2” | 1800 x 930 x 1200 mm 70.8 x 36.6 x 47.2” |

| Internal (workspace) Size (W x D x H) | 770 x 620 x 600 mm 30.3 x 24.4 x 23.6” | 1070 x 620 x 600 mm 42.1 x 24.4 x 23.6” | 1370 x 620 x 600 mm 53.9 x 24.4 x 23.6” | 1670 x 620 x 600 mm 65.7 x 24.4 x 23.6” |

| Production / Test Standard | ISO-14644-1, CE | ISO-14644-1, CE | ISO-14644-1, CE | ISO-14644-1, CE |

| Air Velocity | 0.3 m/s, 60 FPM | 0.4 m/s, 80 FPM | 0.4 m/s, 80 FPM | 0.4 m/s, 80 FPM |

| Workstation Cleanliness | Class-100 (FS 209E) ISO 4, ISO-14644-1 | Class-100 (FS 209E) ISO 4, ISO-14644-1 | Class-100 (FS 209E) ISO 4, ISO-14644-1 | Class-100 (FS 209E) ISO 4, ISO-14644-1 |

| Cabinet Material | Polypropylene | Polypropylene | Polypropylene | Polypropylene |

| Work Surface Material | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel |

| Noise Level | <50dB | <50dB | <54dB | <54dB |

| Power Supply | 110 / 220V, 50/60 Hz, Single phase | 110 / 220V, 50/60 Hz, Single phase | 110 / 220V, 50/60 Hz, Single phase | 110 / 220V, 50/60 Hz, Single phase |

| Illumination | 800 LUX LED lighting | 800 LUX LED lighting | 800 LUX LED lighting | 800 LUX LED lighting |

| Filter Types | HEPA Filter Efficiency @ 99,9997% @ 0.3 Microns H14 (Optional ULPA filter) | HEPA Filter Efficiency @ 99,9997% @ 0.3 Microns H14 (Optional ULPA filter) | HEPA Filter Efficiency @ 99,9997% @ 0.3 Microns H14 (Optional ULPA filter) | HEPA Filter Efficiency @ 99,9997% @ 0.3 Microns H14 (Optional ULPA filter) |

| Model | LAF900-VE | LAF1200-VE | LAF1500-VE | LAF1800-VE |

|---|---|---|---|---|

| External Size (W x D x H) | 900 x 810 x 1350 mm 35 x 31.9 x53.1″ | 1200 x 810 x 1350 mm 47.2 x 31.9 x 53.1″ | 1500 x 810 x 1350 mm 59 x 31.9 x53.1″ | 1800 x 810 x 1350 mm 70.8 x 31.9 x 53.1″ |

| Internal (workspace) Size (W x D x H) | 770 x 660 x 750 mm 30.3 x 26 x 29.5″ | 1070 x 660 x 750 mm 42.1 x 26 x 29.5″ | 1370 x 660 x 750 mm 53.9 x 26 x 29.5″ | 1670 x 660 x 750 mm 65.7 x 26 x 29.5″ |

| Production / Test Standard | ISO-14644-1, CE | ISO-14644-1, CE | ISO-14644-1, CE | ISO-14644-1, CE |

| Air Velocity | 0.3 m/s, 60 FPM | 0.3 m/s, 60 FPM | 0.3 m/s, 60 FPM | 0.3 m/s, 60 FPM |

| Workstation Cleanliness | Class-100 (FS 209E) ISO 4, ISO-14644-1 | Class-100 (FS 209E) ISO 4, ISO-14644-1 | Class-100 (FS 209E) ISO 4, ISO-14644-1 | Class-100 (FS 209E) ISO 4, ISO-14644-1 |

| Cabinet Material | High grade cold rolled steel and surface is static powder coated | High grade cold rolled steel and surface is static powder coated | High grade cold rolled steel and surface is static powder coated | High grade cold rolled steel and surface is static powder coated |

| Work Surface Material | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel |

| Noise Level | <50dB | <50dB | <54dB | <54dB |

| Power Supply | 110 / 220V, 50/60 Hz, Single phase | 110 / 220V, 50/60 Hz, Single phase | 110 / 220V, 50/60 Hz, Single phase | 110 / 220V, 50/60 Hz, Single phase |

| Illumination | 800 LUX LED lighting | 800 LUX LED lighting | 800 LUX LED lighting | 800 LUX LED lighting |

| Filter Types | HEPA Filter Efficiency of 99,9997% at 0.3 Microns H14 (Optional ULPA filter) | HEPA Filter Efficiency of 99,9997% at 0.3 Microns H14 (Optional ULPA filter) | HEPA Filter Efficiency of 99,9997% at 0.3 Microns H14 (Optional ULPA filter) | HEPA Filter Efficiency of 99,9997% at 0.3 Microns H14 (Optional ULPA filter) |

| Model | LAF900-HE | LAF1200-HE | LAF1500-HE | LAF1800-HE |

|---|---|---|---|---|

| External Size (W x D x H) | 900 x 890 x 1250 mm 40.5 x 35 x 49.2 | 1200 x 890 x 1250 mm 47.2 x 35 x 49.2 | 1500x 890 x 1250 mm 59 x 35 x 49.2 | 1800 x 890 x 1250 mm 70.8 x 35 x 49.2 |

| Internal (workspace) Size (W x D x H) | 770 x 610 x 640 mm 30.3 x 24 x 25.2” | 1070 x 610 x 640 mm 47.1 x 24 x 25.2” | 1370 x 610 x 640 mm 53.9 x 24 x 25.2” | 1670 x 610 x 640 mm 65.7 x 24 x 25.2” |

| Production / Test Standard | ISO-14644-1, CE | ISO-14644-1, CE | ISO-14644-1, CE | ISO-14644-1, CE |

| Air Velocity | 0.3 m/s, 60 FPM | 0.3 m/s, 60 FPM | 0.3 m/s, 60 FPM | 0.3 m/s, 60 FPM |

| Workstation Cleanliness | Class-100 (FS 209E) ISO 4, ISO-14644-1 | Class-100 (FS 209E) ISO 4, ISO-14644-1 | Class-100 (FS 209E) ISO 4, ISO-14644-1 | Class-100 (FS 209E) ISO 4, ISO-14644-1 |

| Cabinet Material | High grade cold rolled steel and surface is static powder coated | High grade cold rolled steel and surface is static powder coated | High grade cold rolled steel and surface is static powder coated | High grade cold rolled steel and surface is static powder coated |

| Work Surface Material | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel | 304 Stainless steel |

| Noise Level | <50dB | <50dB | <54dB | <54dB |

| Power Supply | 110 / 220V 50/60 Hz, Single phase | 110 / 220V 50/60 Hz, Single phase | 110 / 220V 50/60 Hz, Single phase | 110 / 220V 50/60 Hz, Single phase |

| Illumination | 800 LUX LED lighting | 800 LUX LED lighting | 800 LUX LED lighting | 800 LUX LED lighting |

| Filter Types | HEPA Filter Efficiency of 99,9997% at 0.3 Microns H14 (Optional ULPA filter) | HEPA Filter Efficiency of 99,9997% at 0.3 Microns H14 (Optional ULPA filter) | HEPA Filter Efficiency of 99,9997% at 0.3 Microns H14 (Optional ULPA filter) | HEPA Filter Efficiency of 99,9997% at 0.3 Microns H14 (Optional ULPA filter) |

So, how is it built? The product features three enclosed sides with a frontal access port and a centrifugal fan located at the back (horizontal) or top (vertical) of the cabinet. The type of unit you choose should depend on the needs of your application. For example, the horizontal system reduces turbulence on the work surface, making it ideal for small-scale samples.