Eliminate Contamination Within Your Workspace

Our Laminar flow cabinets create ISO 5 (Class 100) cleanroom conditions using high-quality H14 HEPA filters and advanced UV technology. These filters remove 99.97% of all airborne particles >0.3 μm in size, eliminating the risk of sample contamination within your workspace. With horizontal and vertical models available, we offer a series of portable, cleanroom alternatives designed to optimise the space inside your facility and reduce operating costs.

TION's manufacturing process enables full cabinet customisation at no additional cost. Our products prioritise safety, accessibility and ergonomics, allowing you to create the perfect cabinet for any application regardless of size. With a suite of gas taps, workbench materials, stands, power sockets and models to choose from, there's no request too complicated for our experienced design teams. Contact our sales department today for more information.

Our optional 316 stainless steel and multi-piece work surfaces can provide a greater degree of corrosive protection and simplify the cleaning process.

ISO 5 standards are used to classify controlled workspace environments based on the number of airborne particles per cubic meter of air.

Lighting is an important part of your laminar flow cabinet specification. Our energy-efficient 800 LUX LED lights provide excellent clarity and last longer than older fluorescent tubes.

Bench-mounted laminar flow cabinets are stationary units fixed to a pre-existing work surface. The products are ideal for laboratories short on space but lack the manoeuvrability of stand-mounted units.

Our upgradable 10.1" digital control panel is touch-screen ready, creating a seamless user experience. The programmable software tracks air inflow and downflow, annual commissioning dates and filter replacements. It's also equipped with a state-of-the-art red-light alarm system. This vital safety function visually notifies the operator if an airflow drop is detected.

Maintaining a safe and secure work zone is paramount to our product design process. Our cabinets adhere to ISO standards and feature a UV sterilisation light to remove contaminants between your working processes.

| Model | LAF900-VP | LAF1200-VP | LAF1500-VP | LAF1800-VP |

|---|---|---|---|---|

| External Size WxDxH (mm) | 900 x 850 x 1320 mm 35.4 x 33.4 x 51.9″ | 1200 x 850 x 1320 mm 47.2 x 33.4 x 51.9″ | 1500 x 850 x 1320 mm 59 x 33.4 x 51.9″ | 1800 x 850 x 1320 mm 70.8 x 33.4 x 51.9″ |

| Workspace WxDxH (mm) | 770 x 700 x 750 mm 30.3 x 27.5 x 29.5″ | 1070 x 700 x 750 mm 42.1 x 27.5 x 29.5” | 1370 x 700 x 750 mm 53.9 x 27.5 x 29.5” | 1670 x 700 x 750 mm 65.7 x 27.5 x 29.5” |

| Noise Level | <52dB | <54dB | <56dB | <56dB |

| Stand Dimensions WxDxH (mm) | 900 x 830 x 735 mm | 1200 x 830 x 735 mm | 1500 x 830 x 735 mm | 1800 x 830 x 735 mm |

| Front Sash Max Opening (mm) | 610 mm / 24" | 610 mm / 24" | 610 mm / 24" | 610 mm / 24" |

| Front Opening Without Sash (mm) | 650 mm / 25.6" | 650 mm / 25.6" | 650 mm / 25.6" | 650 mm / 25.6" |

| Certification | Class-100 (FS 209E) ISO 5, ISO-14644-1 | Class-100 (FS 209E) ISO 5, ISO-14644-1 | Class-100 (FS 209E) ISO 5, ISO-14644-1 | Class-100 (FS 209E) ISO 5, ISO-14644-1 |

| Air Velocity | 0.33 m/s, 66 FPM | 0.33 m/s, 66 FPM | 0.33 m/s, 66 FPM | 0.33 m/s, 66 FPM |

| Cabinet Material | Welded white polypropylene | Welded white polypropylene | Welded white polypropylene | Welded white polypropylene |

| Work Table Material | 304 stainless steel | 304 stainless steel | 304 stainless steel | 304 stainless steel |

| Filter Types | 1 x HEPA H14 filter with an efficiency of 99,9995% at 0.3 Microns (ULPA filters are also available) | 1 x HEPA H14 filter with an efficiency of 99,9995% at 0.3 Microns (ULPA filters are also available) | 1 x HEPA H14 filter with an efficiency of 99,9995% at 0.3 Microns (ULPA filters are also available) | 1 x HEPA H14 filter with an efficiency of 99,9995% at 0.3 Microns (ULPA filters are also available) |

| Control System | 10.1" full-colour touch screen with low airflow alarms, filter change and service timers, red-light alarms (audio & visual), eco mode and an optional integrated particle monitoring system | 10.1" full-colour touch screen with low airflow alarms, filter change and service timers, red-light alarms (audio & visual), eco mode and an optional integrated particle monitoring system | 10.1" full-colour touch screen with low airflow alarms, filter change and service timers, red-light alarms (audio & visual), eco mode and an optional integrated particle monitoring system | 10.1" full-colour touch screen with low airflow alarms, filter change and service timers, red-light alarms (audio & visual), eco mode and an optional integrated particle monitoring system |

| Power Supply Options | 110 / 220V, 50/60 Hz, single phase | 110 / 220V, 50/60 Hz, single phase | 110 / 220V, 50/60 Hz, single phase | 110 / 220V, 50/60 Hz, single phase |

| Illumination | 800 LUX, eco-friendly LED lighting | 800 LUX, eco-friendly LED lighting | 800 LUX, eco-friendly LED lighting | 800 LUX, eco-friendly LED lighting |

| UV Light | Waterproof, germicidal UV sterilisation light operating at 254nm | Waterproof, germicidal UV sterilisation light operating at 254nm | Waterproof, germicidal UV sterilisation light operating at 254nm | Waterproof, germicidal UV sterilisation light operating at 254nm |

| Customisation Options | Taps: (water, gas, nitrogen, vacuum, others), sinks, sumps, shelves, sash, partitions, dimensions and height adjustable stands | Taps: (water, gas, nitrogen, vacuum, others), sinks, sumps, shelves, sash, partitions, dimensions and height adjustable stands | Taps: (water, gas, nitrogen, vacuum, others), sinks, sumps, shelves, sash, partitions, dimensions and height adjustable stands | Taps: (water, gas, nitrogen, vacuum, others), sinks, sumps, shelves, sash, partitions, dimensions and height adjustable stands |

| Model | LAF900-HP | LAF1200-HP | LAF1500-HP | LAF1800-HP |

|---|---|---|---|---|

| External Size WxDxH (mm) | 900 x 930 x 1320 mm 35.4 x 36.6 x 51.9” | 1200 x 930 x 1320 mm 47.2” x 36.6 x 51.9” | 1500 x 930 x 1320 mm 59 x 36.6 x 51.9” | 1800 x 930 x 1320 mm 70.8 x 36.6 x 51.9” |

| Workspace WxDxH (mm) | 770 x 620 x 600 mm 30.3 x 24.4 x 23.6” | 1070 x 620 x 600 mm 42.1 x 24.4 x 23.6” | 1370 x 620 x 600 mm 53.9 x 24.4 x 23.6” | 1670 x 620 x 600 mm 65.7 x 24.4 x 23.6” |

| Noise Level | <52dB | <54dB | <56dB | <56dB |

| Stand Dimensions WxDxH (mm) | 900 x 910 x 735 mm | 1200 x 910 x 735 mm | 1500 x 910 x 735 mm | 1800 x 910 x 735 mm |

| Front Sash Max Opening (mm) | 610 mm / 24" | 610 mm / 24" | 610 mm / 24" | 610 mm / 24" |

| Front Opening Without Sash (mm) | 650 mm / 25.6" | 650 mm / 25.6" | 650 mm / 25.6" | 650 mm / 25.6" |

| Certification | Class-100 (FS 209E) ISO 5, ISO-14644-1 | Class-100 (FS 209E) ISO 5, ISO-14644-1 | Class-100 (FS 209E) ISO 5, ISO-14644-1 | Class-100 (FS 209E) ISO 5, ISO-14644-1 |

| Air Velocity | 0.33 m/s, 66 FPM | 0.33 m/s, 66 FPM | 0.33 m/s, 66 FPM | 0.33 m/s, 66 FPM |

| Cabinet Material | Welded white polypropylene | Welded white polypropylene | Welded white polypropylene | Welded white polypropylene |

| Work Table Material | 304 stainless steel | 304 stainless steel | 304 stainless steel | 304 stainless steel |

| Filter Types | 1 x HEPA H14 filter with an efficiency of 99,9995% at 0.3 Microns (ULPA filters are also available) | 1 x HEPA H14 filter with an efficiency of 99,9995% at 0.3 Microns (ULPA filters are also available) | 1 x HEPA H14 filter with an efficiency of 99,9995% at 0.3 Microns (ULPA filters are also available) | 1 x HEPA H14 filter with an efficiency of 99,9995% at 0.3 Microns (ULPA filters are also available) |

| Control System | 10.1" full-colour touch screen with low airflow alarms, filter change and service timers, red-light alarms (audio & visual), eco mode and optional integrated particle monitoring system | 10.1" full-colour touch screen with low airflow alarms, filter change and service timers, red-light alarms (audio & visual), eco mode and optional integrated particle monitoring system | 10.1" full-colour touch screen with low airflow alarms, filter change and service timers, red-light alarms (audio & visual), eco mode and optional integrated particle monitoring system | 10.1" full-colour touch screen with low airflow alarms, filter change and service timers, red-light alarms (audio & visual), eco mode and optional integrated particle monitoring system |

| Power Supply Options | 110 / 220V, 50/60 Hz, single phase | 110 / 220V, 50/60 Hz, single phase | 110 / 220V, 50/60 Hz, single phase | 110 / 220V, 50/60 Hz, single phase |

| Illumination | 800 LUX, eco-friendly LED lighting | 800 LUX, eco-friendly LED lighting | 800 LUX, eco-friendly LED lighting | 800 LUX, eco-friendly LED lighting |

| UV Light | Waterproof, germicidal UV sterilisation light operating at 254nm | Waterproof, germicidal UV sterilisation light operating at 254nm | Waterproof, germicidal UV sterilisation light operating at 254nm | Waterproof, germicidal UV sterilisation light operating at 254nm |

| Customisation Options | Taps: (water, gas, nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, dimensions and height adjustable stands | Taps: (water, gas, nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, dimensions and height adjustable stands | Taps: (water, gas, nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, dimensions and height adjustable stands | Taps: (water, gas, nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, dimensions and height adjustable stands |

| Model | LAF900-VE | LAF1200-VE | LAF1500-VE | LAF1800-VE |

|---|---|---|---|---|

| External Size WxDxH (mm) | 900 x 850 x 1220 mm 35.4 x 33.4 x 48" | 1200 x 850 x 1220 mm 47.2 x 33.4 x 48" | 1500 x 850 x 1220 mm 59 x 33.4 x 48" | 1800 x 850 x 1220 mm 70.8 x 33.4 x 48" |

| Workspace WxDxH (mm) | 770 x 620 x 600 mm 30.3 x 24.4 x 23.6" | 1070 x 620 x 600 mm 42.1 x 24.4 x 23.6" | 1370 x 620 x 600 mm 53.9 x 24.4 x 23.6" | 1670 x 620 x 600 mm 65.7 x 24.4 x 23.6" |

| Noise Level | <52dB | <54dB | <56dB | <56dB |

| Stand Dimensions WxDxH (mm) | 900 x 830 x 735 mm | 1200 x 830 x 735 mm | 1500 x 830 x 735 mm | 1800 x 830 x 735 mm |

| Front Sash Max Opening (mm) | 610 mm / 24" | 610 mm / 24" | 610 mm / 24" | 610 mm / 24" |

| Front Opening Without Sash (mm) | 650 mm / 25.6" | 650 mm / 25.6" | 650 mm / 25.6" | 650 mm / 25.6" |

| Certification | Class-100 (FS 209E) ISO 5, ISO-14644-1 | Class-100 (FS 209E) ISO 5, ISO-14644-1 | Class-100 (FS 209E) ISO 5, ISO-14644-1 | Class-100 (FS 209E) ISO 5, ISO-14644-1 |

| Air Velocity | 0.33 m/s, 66 FPM | 0.33 m/s, 66 FPM | 0.33 m/s, 66 FPM | 0.33 m/s, 66 FPM |

| Cabinet Material | Metal with epoxy-coated paint | Metal with epoxy-coated paint | Metal with epoxy-coated paint | Metal with epoxy-coated paint |

| Work Table Material | 304 stainless steel | 304 stainless steel | 304 stainless steel | 304 stainless steel |

| Filter Types | 1 x HEPA H14 filter with an efficiency of 99,9995% at 0.3 Microns (ULPA filters are also available) | 1 x HEPA H14 filter with an efficiency of 99,9995% at 0.3 Microns (ULPA filters are also available) | 1 x HEPA H14 filter with an efficiency of 99,9995% at 0.3 Microns (ULPA filters are also available) | 1 x HEPA H14 filter with an efficiency of 99,9995% at 0.3 Microns (ULPA filters are also available) |

| Control System | 7" full-colour touch screen with filter replacement alarm, hour counter and optional integrated particle monitoring system | 7" full-colour touch screen with filter replacement alarm, hour counter and optional integrated particle monitoring system | 7" full-colour touch screen with filter replacement alarm, hour counter and optional integrated particle monitoring system | 7" full-colour touch screen with filter replacement alarm, hour counter and optional integrated particle monitoring system |

| Power Supply Options | 110 / 220V, 50/60 Hz, single phase | 110 / 220V, 50/60 Hz, single phase | 110 / 220V, 50/60 Hz, single phase | 110 / 220V, 50/60 Hz, single phase |

| Illumination | 800 LUX LED lighting | 800 LUX LED lighting | 800 LUX LED lighting | 800 LUX LED lighting |

| UV Light | Waterproof, germicidal UV sterilisation light operating at 254nm | Waterproof, germicidal UV sterilisation light operating at 254nm | Waterproof, germicidal UV sterilisation light operating at 254nm | Waterproof, germicidal UV sterilisation light operating at 254nm |

| Customisation Options | Taps: (water, gas, nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, dimensions and height adjustable stands | Taps: (water, gas, nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, dimensions and height adjustable stands | Taps: (water, gas, nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, dimensions and height adjustable stands | Taps: (water, gas, nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, dimensions and height adjustable stands |

| Model | LAF900-HE | LAF1200-HE | LAF1500-HE | LAF1800-HE |

|---|---|---|---|---|

| External Size WxDxH (mm) | 900 x 930 x 1220 mm 35.4 x 36.6 x 48" | 1200 x 930 x 1220 mm 47.2 x 36.6 x 48" | 1500 x 930 x 1220 mm 59 x 36.6 x 48" | 1800 x 930 x 1220 mm 70.8 x 36.6 x 48" |

| Workspace WxDxH (mm) | 770 x 620 x 600 mm 30.3 x 24.4 x 23.6" | 1070 x 620 x 600 mm 42.1 x 24.4 x 23.6" | 1370 x 620 x 600 mm 53.9" x 24.4" x 23.6" | 1670 x 620 x 600 mm 65.7 x 24.4 x 23.6" |

| Noise Level | <52dB | <54dB | <56dB | <56dB |

| Stand Dimensions WxDxH (mm) | 900 x 910 x 735 mm | 1200 x 910 x 735 mm | 1500 x 910 x 735 mm | 1800 x 910 x 735 mm |

| Front Sash Max Opening (mm) | 610 mm / 24" | 610 mm / 24" | 610 mm / 24" | 610 mm / 24" |

| Front Opening Without Sash (mm) | 650 mm / 25.6" | 650 mm / 25.6" | 650 mm / 25.6" | 650 mm / 25.6" |

| Certification | Class-100 (FS 209E) ISO 5, ISO-14644-1 | Class-100 (FS 209E) ISO 5, ISO-14644-1 | Class-100 (FS 209E) ISO 5, ISO-14644-1 | Class-100 (FS 209E) ISO 5, ISO-14644-1 |

| Air Velocity | 0.33 m/s, 66 FPM | 0.33 m/s, 66 FPM | 0.33 m/s, 66 FPM | 0.33 m/s, 66 FPM |

| Cabinet Material | Metal with epoxy-coated paint | Metal with epoxy-coated paint | Metal with epoxy-coated paint | Metal with epoxy-coated paint |

| Work Table Material | 304 stainless steel | 304 stainless steel | 304 stainless steel | 304 stainless steel |

| Filter Types | 1 x HEPA H14 filter with an efficiency of 99,9995% at 0.3 Microns (ULPA filters are also available) | 1 x HEPA H14 filter with an efficiency of 99,9995% at 0.3 Microns (ULPA filters are also available) | 1 x HEPA H14 filter with an efficiency of 99,9995% at 0.3 Microns (ULPA filters are also available) | 1 x HEPA H14 filter with an efficiency of 99,9995% at 0.3 Microns (ULPA filters are also available) |

| Control System | 7" full-colour touch screen with filter replacement alarm, hour counter and optional integrated particle monitoring system | 7" full-colour touch screen with filter replacement alarm, hour counter and optional integrated particle monitoring system | 7" full-colour touch screen with filter replacement alarm, hour counter and optional integrated particle monitoring system | 7" full-colour touch screen with filter replacement alarm, hour counter and optional integrated particle monitoring system |

| Power Supply Options | 110 / 220V, 50/60 Hz, single phase | 110 / 220V, 50/60 Hz, single phase | 110 / 220V, 50/60 Hz, single phase | 110 / 220V, 50/60 Hz, single phase |

| Illumination | 800 LUX LED lighting | 800 LUX LED lighting | 800 LUX LED lighting | 800 LUX LED lighting |

| UV Light | Waterproof, germicidal UV sterilisation light operating at 254nm | Waterproof, germicidal UV sterilisation light operating at 254nm | Waterproof, germicidal UV sterilisation light operating at 254nm | Waterproof, germicidal UV sterilisation light operating at 254nm |

| Customisation Options | Taps: (water, gas, nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, dimensions and height adjustable stands | Taps: (water, gas, nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, dimensions and height adjustable stands | Taps: (water, gas, nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, dimensions and height adjustable stands | Taps: (water, gas, nitrogen, vacuum, others), sinks, sumps, shelves, multi-sash, partitions, dimensions and height adjustable stands |

The first concept of "laminar flow air" originated during the late 1950s. Willis Whitfield developed the first laminar flow cleanroom in 1959 during his tenure at Sandia National Laboratories. Essentially, you can think of a laminar flow cabinet as a small-scale cleanroom with an ISO rating to match the level of cleanliness the workspace provides. While some laminar flow cabinets create ISO 4 cleanroom conditions, others create ISO 5. The level of cleanliness you need depends on the application or process the product is required for.

In theory, these devices also function similarly to a biosafety cabinet. However, unlike a biosafety cabinet, laminar flow cabinets do not protect the operator, only the sample. For example, if you have an application involving a benign, non-toxic material, a laminar flow cabinet would be a suitable device. On the other hand, if the material is potentially hazardous or zoonotic in nature, a class I, II or III biosafety cabinet would need to be used.

Laminar flow cabinets are available in two configurations, vertical and horizontal. Typically, the products also feature a germicidal UV-C lamp to cleanse the worksurface between tests, reducing the likelihood of cross-contamination.

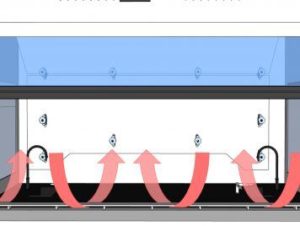

The products are available in two configurations, horizontal and vertical. The type of unit you choose depends on the nature of the application. A horizontal laminar flow cabinet directs filtered air from the back of the unit towards the operator. On the other hand, a vertical laminar flow cabinet directs filtered air from the top of the unit onto the work surface. Although both designs maintain the integrity of the sterile environment, vertical laminar flow cabinets are often preferred thanks to increased operator comfort and equipment storage space. For information on the differences between these two units, please visit: "Horizontal Vs Vertical Laminar Flow Cabinets".

To ensure your cabinet functions correctly, follow the recommended operator guidelines. When switching the unit on, double-check your airflows and move the sash to the correct working height. Next, minimise movement to prevent airflow disruption and avoid clutter inside the workspace.

Typically, you would only choose ULPA filters when working with fine particles or to increase the level of cleanliness. For example, ULPA filters can produce ISO 3 cleanroom conditions, while HEPA filters produce ISO 5.

For more information on the benefits of HEPA filters, please visit "What Are HEPA Filters and How Do they Work?".

Laminar flow cabinets specialise in creating ISO cleanroom conditions suitable for medical device assembly, manufacturing, packaging and pharmaceutical production. More specialised applications include optical lens assembly, semiconductor work, data recovery, and the preparation of sterile tissue cultures. These are applications where product sterility and particulate control are critical.

In short, choosing the correct cabinet depends on the materials you’re working with and the type of protection required. Laminar flow cabinets are ideal for clean, sterile operations involving non-hazardous materials. For hazardous biological work, a biosafety cabinet is required. When working with chemical fumes or corrosive vapours, a properly ventilated fume cupboard is the safe and appropriate choice.

Always follow your risk assessment and safety guidelines to select the right equipment for your needs. Alternatively, you can contact our team for more information or read "What Are Laminar Flow Cabinets Most Commonly Used For".

You should ensure the area is clear of equipment before commencing the installation process to minimise downtime. If the unit needs to be integrated with external laboratory systems, this could add another hour or two, depending on the complexity of the project.

Next, you should consider the commissioning and certification of the unit. Before use, the cabinet must be tested to ensure it meets ISO standards, which includes checking HEPA filter integrity and airflow velocity. This process can take a few hours and must be performed by a qualified engineer.

Altogether, for a straightforward installation in a ready-to-use lab, you can expect the entire process — from delivery to certification — to take about half a day.

Your laminar flow cabinet provider should include a listed breakdown of costs in the quotation process. At TION, we list these modifications as "Optional Extras", appearing separate from the standard base product.

If costs are a deciding factor in your quotation, you can edit the specification or change the model of your product. For example, we have two baseline models, Pro laminar flow cabinets and Essential laminar flow cabinets.

The difference between these two ranges lies in the building materials. The Pro model is built from medical-grade welded polypropylene while the Essential range is built from mild steel.

Read our Privacy Policy for more information on how we collect and process data.

No thank you

Read our Privacy Policy for more information on how we collect and process data.