Following on from our previous article on horizontal vs vertical LAF cabinets, it's time to look at another crucial decision. What is the best option—a ductless fume cupboard or a ducted fume cupboard?

Truthfully, it is impossible to give an answer in favour of either concept without objectively analysing the disadvantages and advantages of both systems. It is also impossible to give an answer to the ducted vs ductless fume hood question without prior knowledge of the intended usage. Therefore, to help make a qualified decision, it is important to examine how and where the hood will be used.

Equally as important is to determine what will happen within the hood and how each hood type affects its environment. Objectively analysing the disadvantages and advantages of both systems requires exact knowledge of chemical usage and project type.

Only once the usage scenario has been clearly established can a decision be made in favour of using either system. Aside from helping make the right decision, the goal of this article is also to eliminate any preconceived negative notions against one system or the other so as to allow users to find the best solution in terms of environmental impact, cost, and adaptability of use, without losing sight of the fact that the solution should ultimately ensure their safety.

Most, if not all laboratory personnel are knowledgeable about ducted fume hoods. In fact, the basic concept dates back to the Middle Ages, when the alchemists used the chimneys of their own homes to perform experiments. Since then this concept, which never ceased to evolve, has finally turned into the modern ducted fume hoods of today's laboratories.

Click here to browse our range of ducted fume cupboards.

In contrast, recirculating filtered fume hoods have only been around for about 50 years. The concept can be linked back to the first gas mask (created in 1847), whereby air is filtered before being recirculated, and the first activated charcoal gas mask created in 1915.

Ductless cupboards were first created around 1968. Today, ductless filtering fume enclosures use the properties of activated carbon combined with catalysts and certain neutralisers in order to filter toxic molecules and HEPA or ULPA filters are used to filter out dust and particles, therefore eliminating their dependency on HVAC and the need to be connected to external ductwork. Filter technology has advanced to the stage where a large percentage of experiments or processes can be carried out safely in a ductless cupboard. However, you still need to make sure you regularly clean and take care of your filters.

Click here to browse our range of ductless fume cupboards.

The installation of a ducted fume hood is complex. Extensive engineering studies are needed beforehand to determine proper rooftop ventilation and ductwork requirements along with the make-up air system that will be necessary to compensate for the air consumed by one or more fume hoods. The costs of ductwork and fans (and the installation of) is significant.

Since a ducted cupboard consumes more energy per year than an average house, the consumption of heated or cooled air is high and can represent for a 1500mm modern fume hood an average of 1076 m3 per hour (9,425,760 m3 per year [assuming 24/7/365]). Recently updated calculations show that this energy consumption translates to an estimated minimum of £1017.00 per year.

Lastly, their working principle forces ducted fume cupboards to eject toxic substances directly into the atmosphere, and their fixed nature and tie-in to the HVAC system render them immobile. Even if scrubbing media is used there is still the issue of waste chemicals to dispose of, and if a charcoal bed is used, the waste carbon.

Today, fume hoods that entail ducting have reached a high level of sophistication and, if a Variable Air Volume system is present, with regard to saving the air exhausted into the atmosphere and containing the fumes around the work area. They do not require such a detailed pre-verification of the chemicals intended for use, aside from those prohibited by laws and regulations, which as of today do not limit the amount of chemicals they can exhaust into the atmosphere. The only consideration is the work surface required and whether a scrubber is needed (for example with Perchloric acids).

Traditional fume hoods have been long recognised as an effective means of protection for laboratory personnel, although recently they have been identified as a large consumer of energy in comparison to those that use filters, which can’t be ignored.

The frame of use of a ductless filtering fume enclosure is limited to certain chemicals. This limitation can vary between manufacturers, which is why it is important to consult each manufacturer's guide of retained chemicals or chemical listing to determine the TWA (time-weighted average over an 8 hour period) maximum exposure rates. Filters are only able to remove chemicals down to a set ppm and some chemicals can be as low as 2ppm TWA!.

Another disadvantage can be the amount of chemicals being used – especially if boiling off large quantities of acids where a lot of moisture is generated as fume cupboard filters have a finite adsorption capacity. It is recommended to monitor filter saturation in any situation (for example a built-in filter alarm). It is necessary as well to periodically replace the filters (recommended annually or 600 hours use, whichever occurs sooner).

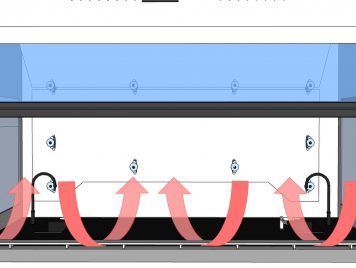

Recirculating fume cupboards do not require external fans/ductwork/exhaust ducts or make-up air systems since they filter and recycle the laboratory air. They don't exhaust chemical pollutants into the atmosphere and they are mobile, so can be moved to suit changing laboratory environments. Fume hoods that are built with filters instead of ducting are immediately available for use without lengthy or costly installation requirements. They can be temporarily stored and dispatched where needed by a safety officer for a scheduled class or project and also be placed anywhere at a moment's notice to protect users in cases in which the need suddenly arises.

The fact is that when an application falls within the intended frame of usage, as set by the manufacturer, one cannot help but be drawn to the advantages of a ductless filtering fume hood. However, it is very important at this moment to verify that the manufacturer has answered all of the necessary questions that must be asked prior to making a final decision, such as:

If each and every one of these questions receives a positive response, one's decision is documented and should now be easy to make. However, attention must be given to the fact that certain ductless enclosure manufacturers do not hesitate to provide positive answers to all of these questions for the sole purpose of making a sale. It is therefore advisable to deal strictly with manufacturers that are able to show official proof of compliance with the performance standard BS EN 14175 (NOT just stating 'designed to comply with').

This indispensable precaution will help protect the buyer from certain companies involved in this emerging profession, which need more rigorous product design and sales approaches. Complying with a stringent safety standard can only benefit all parties involved and primarily guarantees the safety of end-users.

In the event that satisfactory responses cannot be provided to ensure the safe usage of a recirculating fume hood, a decision should certainly be made in favour of selecting a ducted fume hood. Without a doubt, safety must remain the first priority when making this decision. Whether the lab is in a school or a blue-chip organisation, this is vital. However, while ducted enclosures have been the industry standard for containment of toxic gases for years, their tremendous infrastructure, usage, and environmental costs cannot be ignored any longer.

At the same time, some ductless fume hood manufacturers have recently emerged with safety services and product evolutions, which, under the right circumstances, can provide a viable solution in the laboratory. In today's world, the decision between the two styles needs to be made with a careful eye on safety, the environment, and energy consumption, and a conclusion can be made that it is worthwhile to try and determine where both products have their place. Given the extreme rise in energy costs and the benefits of using green technologies, taking the time to figure out which system is best where, and determining the applications most suitable to each can have a significant impact on one's budget and on the environment.

If you have questions about the benefits of ducted fume cupboards versus ductless fume cupboards, or vice versa, please don't hesitate to contact one of our expert team.

Read our Privacy Policy for more information on how we collect and process data.

No thank you

Read our Privacy Policy for more information on how we collect and process data.