High Efficiency Particulate Air (HEPA) filters are effective devices used in cleanrooms, IVF labs, and healthcare environments to help provide clean air and reliable ventilation. They're an important part of any ventilation system.

HEPA filters are tested throughout manufacturing and must pass rigorous commissioning tests before they're made available to the market. Their role is crucial, and it's important that they operate as intended.

So, what happens when they're purchased, installed, and heavily used in these environments? How can you test your filter to ensure that it's still performing to the necessary standard?

Expert teams are required to inspect these specialist facilities and make sure they're up to scratch every 6 months. Dispersed oil particulate (DOP) testing is a fundamental part of this and is used to confirm that HEPA filters provide purified air.

These filters are mechanical parts. And like any other mechanical part, they're prone to faults and breaking down, and therefore need to be regularly inspected and tested to keep them in the best possible condition.

Ventilation systems need to be maintained and serviced when they're used in specialist environments. The HEPA filters within these systems are tasked with removing dust, pathogens, and other tiny micro-organisms from the air to provide clean, bacteria-free air instead.

Particularly in healthcare environments and IVF labs, there's no room for compromise – if a HEPA filter performs so much as 1% below the expected standards, there could be significant effects further down the line. Strict regulation ensures the ventilation system consistently performs at the expected standard. Should it fail any performance test, then failing parts can be replaced.

On top of that, cleanrooms, for example, need to be tested, analysed, and validated every 6 months. These controlled environments must regularly undergo a series of tests to ensure they are meeting regulatory guidelines and that the space is safe and controlled.

And this is where DOP testing comes in. DOP testing is an essential part of the maintenance and validation of these controlled environments and it will quickly identify faults in a HEPA filter and ventilation system. This confirms whether or not they are meeting the required standards.

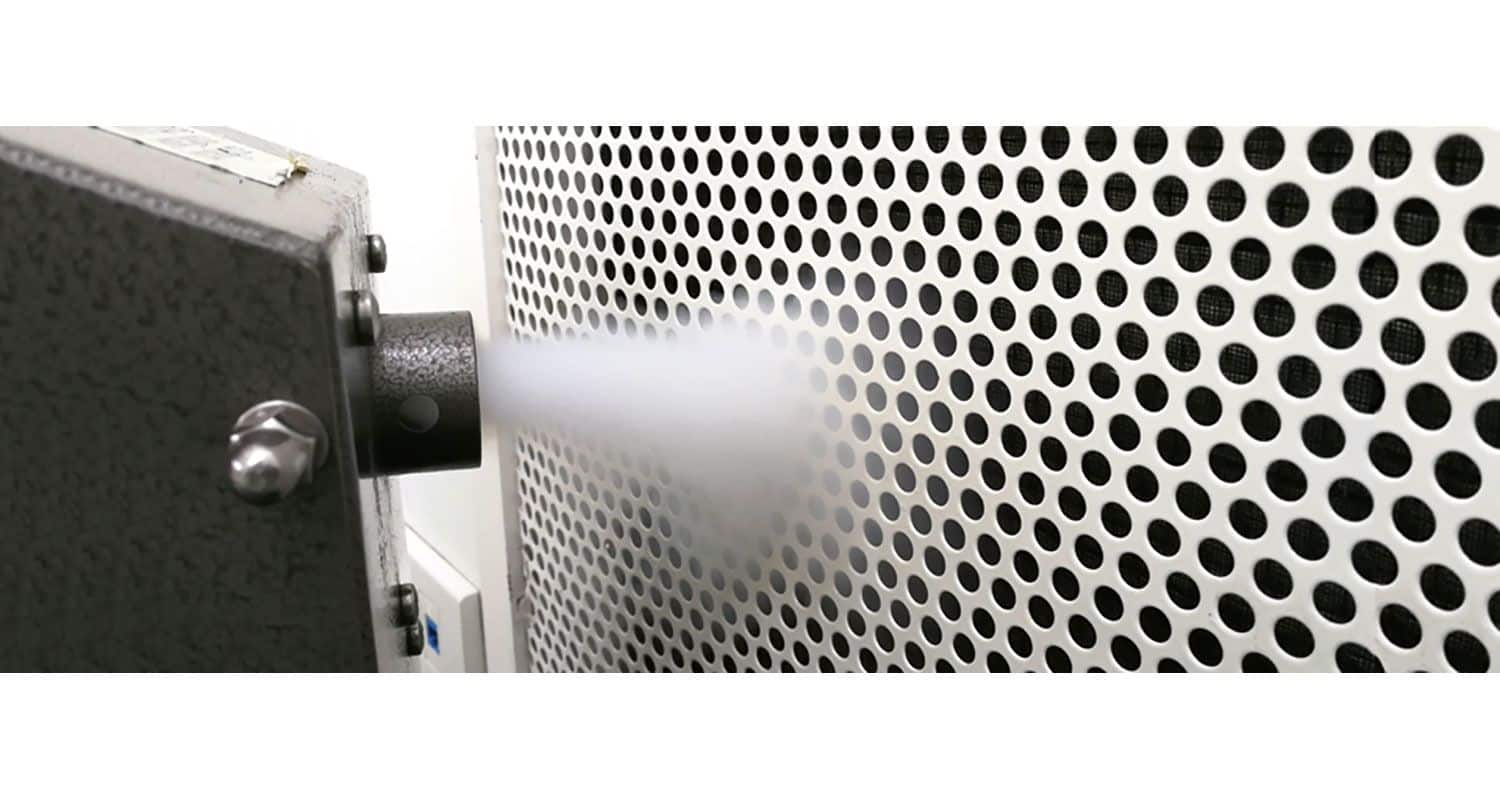

DOP testing is straightforward on paper. It involves the oil particulate, which comes in the form of an aerosol. A high concentration of the particulate is released into the test area’s airstream (upstream of the filter). Measurements are then taken with a calibrated photometer to establish whether or not the particulate has made its way through either the filter or its casing downstream.

This simple process challenges the seals, housing, joints, filter, and frame of the HEPA mechanism and will quickly identify any leaks.

DOP testing follows a strict procedure and should therefore only be carried out by professional testing teams.

First of all, the testing team will need to follow a strict, compliant procedure to ensure that the filters are tested in a reliable way. After a detailed inspection, a suitable injection point is identified and an injection mechanism will also need to be designed.

The ventilation system needs to be isolated from any power sources, and pumps may even need to be installed in order to create sufficient pressure suction.

Thereafter, two engineers need to synchronise their activities and make sure that accurate readings are being recorded by the photometer. Depending on the results, the concentration of aerosol may need to be increased or decreased during the test.

Any equipment that uses HEPA filters, whether it be an air purifier or fume cupboard, will be issued a certificate upon passing the test, and each of the parts will be labelled until there is a requirement for another test.

As well as testing the condition of your ventilation system, a DOP test can also identify whether or not all of the air is passing through the filter. Professional teams will be able to observe 'dead spots' with limited activity where dangerous contaminations might build up. It will also involve portable appliance testing (PAC).

Keep your environment under strict control and ensure that your team is working in a safe, secure, and sterile workplace with regular DOP testing for any HEPA filters on site. To find out more about DOP testing for your HEPA filters, get in touch today.

Read our Privacy Policy for more information on how we collect and process data.

No thank you

Read our Privacy Policy for more information on how we collect and process data.